Manage Your PSM, Quality and Regulatory Programs with Intelex

Simplify the way you track, analyze, and report with Intelex’s 40+ out-of-the-box applications for chemical manufacturing and processing.

Trusted by Leading Manufacturing Organizations Around the World

Connect Your Day-To-Day Work with Company-Wide Goals

Intelex helps chemical companies strengthen safety, quality, and environmental performance with integrated solutions that support ISO 45001, 9001, 14001, and ANSI Z10. Whether you're building foundational safety programs or managing complex PSM and regulatory requirements, Intelex gives you a centralized system to reduce risk, simplify compliance, and drive continuous improvement.

Drive Engagement Across All Levels

Leaders can make faster, more confident decisions with configurable dashboards and site-level reporting that delivers visibility into process safety, equipment risks, compliance exposures and ongoing improvement efforts.

Use leading indicators like near-misses, observations, training status, process hazard analyses and audit/inspection findings for better decision making at the plant level.

Frontline workers can easily notify management of safety concerns through mobile technology, and safety teams can push critical information to the organization.

Manage Process Safety and Risks

Connect MOC, PHAs, SOPs, and training records in a single, centralized platform.

Ensure that every change, procedure, risk assessment and competency update is traceable, current, and aligned to regulatory requirements with automated workflows, role-based access, and built-in audit trails.

Create a closed-loop system where incidents, findings, and process hazard analyses are linked, lessons are learned, and risks aren’t repeated.

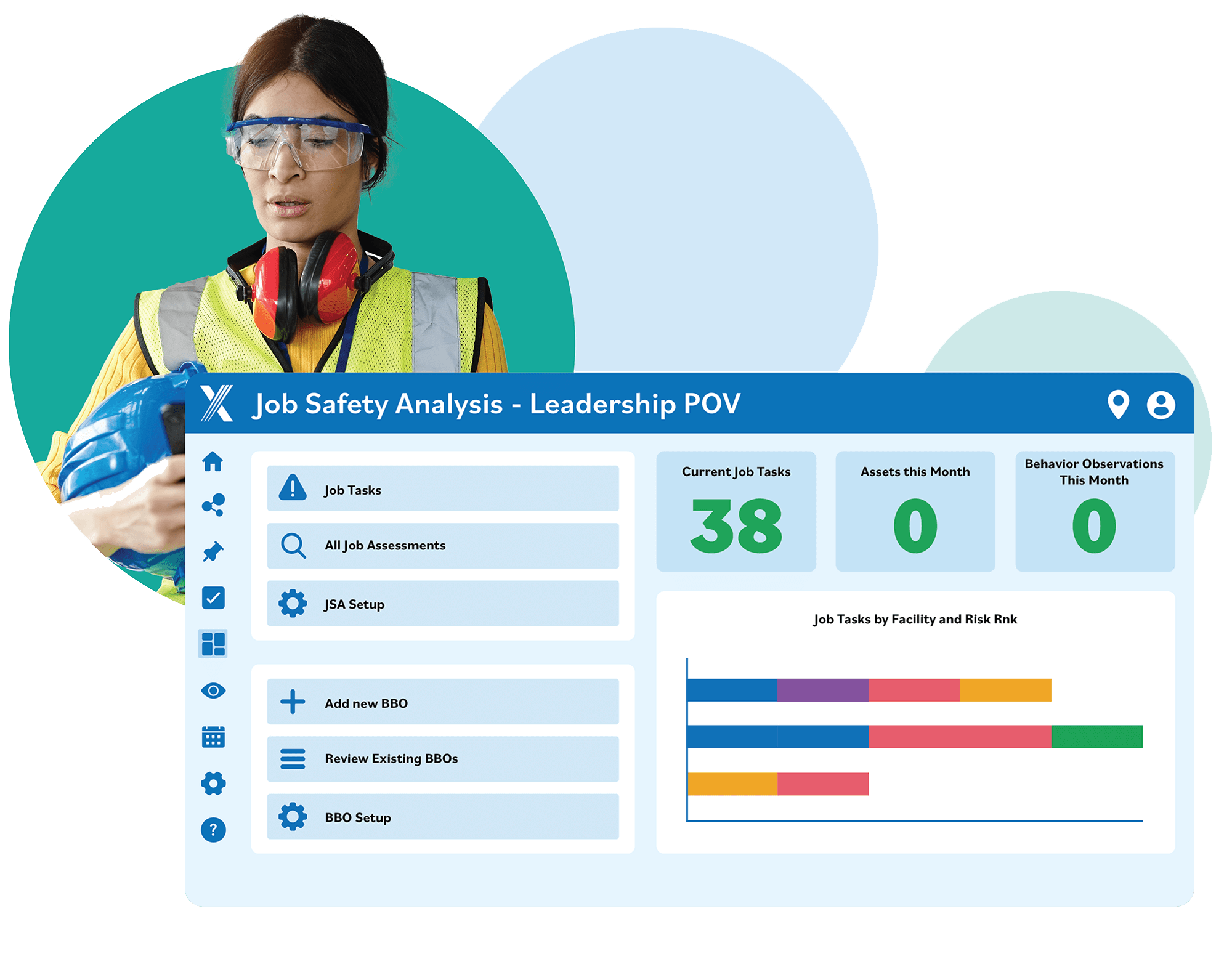

Meet Every Regulatory Requirement

See all compliance requirements across the organization from a single source of truth.

Never worry about changing regulations again. Intelex integrates with regulatory content providers like Enhesa and RegScan to push updates into compliance plans and SOP reviews.

Quickly verify statuses of critical compliance items with centralized task management and ensure responsible individuals are notified of expectations and due dates with role-based notifications.

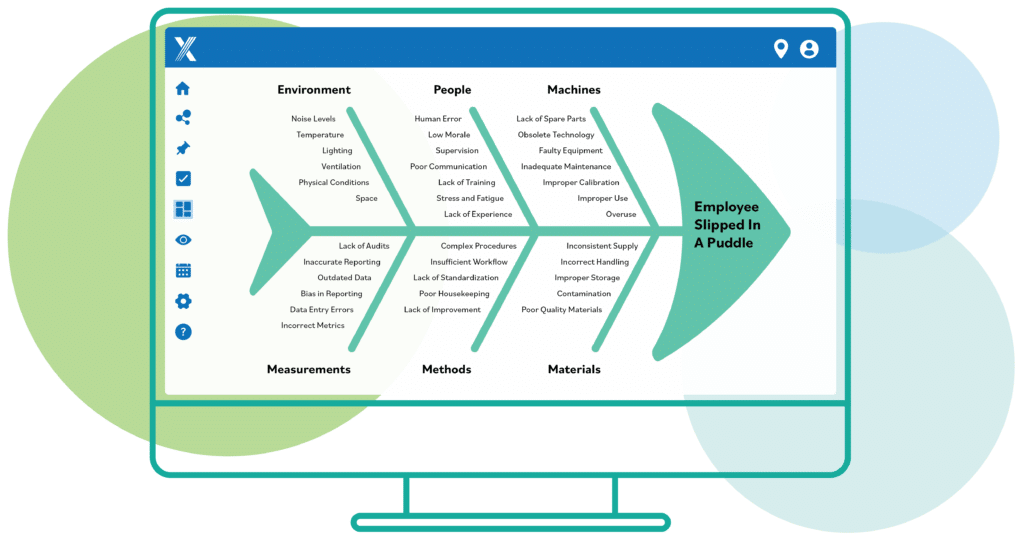

Understand and Prevent Incidents

Everyone can quickly report incidents, even when offline, with Intelex’s mobile reporting. Snap a photo, tag the location, and escalate issues in seconds.

Connect investigations, causes, and actions without extra steps thanks to embedded Fishbone, 5-Whys, and RCA tools in your reporting process.

Link incidents, investigations, and corrective actions in one record, making it easy to share lessons learned across your organization.

Montior Industrial Hygiene and Exposure Risks

Efficiently manage your IH program with centralized exposure groups, risk assessments, sample scheduling, data collection, analysis, and improvement actions in a single, streamlined workflow.

Easily see where IH risks are highest by connecting data across sites, exposure groups, and people, making it simple to prioritize actions.

House Your Chemical Management System on One Platform

Intelex offers a broad spectrum of applications. While your organization likely won’t need every solution, the flexibility of our platform means you can choose the tools that align with your unique priorities to improve efficiency, strengthen business continuity, and drive better financial performance.

EHS Management Solution

Centralize critical process safety management tasks, track leading and lagging indicators in real time, and connect key processes in one integrated platform.

Process Safety Management Solution

Unify your entire safety program in one system built for global visibility and consistency. With a single source of truth for every process and record, you can streamline compliance, strengthen safety culture, and ensure teams adopt a connected, standardized approach to managing risk.

Environmental Management Solution

Reduce the risk of fines, penalties, and costly mistakes by centralizing permitting and compliance tasks. Automated tracking and alerts help you avoid human error, stay on top of deadlines, and maintain full confidence in meeting every obligation.

Quality Management Solution

Automate the entire PDCA cycle with a single system that drives continuous improvement from start to finish. Identify problems, test solutions, verify effectiveness, and implement changes, all while automating data capture, analysis, and reporting. With real-time visibility across every step, you can prevent nonconformance, protect quality, and cut the costs of rework and delays.

Integrates With Your Existing Tech Stack

Easily connect Intelex to your ERP, HR, LMS, and reporting tools with minimal IT effort. You can also expand your capabilities through partners like Enhesa and TapRooT®, making it easy to scale compliance, investigations, and risk management across the business.

Watch a Demo of Intelex’s Chemicals Safety Solution

See how our cloud-based platform helps chemical industry simplify safety processes, drive compliance, and build a resilient safety culture.

CASE STUDY

How Air Liquide Canada Maintains Certification for ISO 9001 with Intelex

“We chose Intelex because we believe software should adapt to the company, rather than the company adapting to the software.”

Gary Smit

Director of Quality Management

Air Liquide

- ~1,500 users accessing the system

- Maintained ISO 9001 certification

- Improved employee ownership over quality process

Frequently Asked Questions

Chemical companies often rely on spreadsheets or siloed systems that create reporting bottlenecks. With automation, tasks like discharge monitoring, KPI reporting, and OH process tracking can be streamlined. This saves time, reduces human error, and frees up staff to focus on higher-value safety and compliance activities.

The chemicals sector faces strict oversight from OSHA, EPA, REACH, and GHS standards. A centralized system of record enables transparency across sites, simplifies global incident reporting, and ensures audit readiness. By consolidating information, teams gain accountability, consistency, and the ability to respond quickly during inspections or compliance checks.

Safety is non-negotiable in chemicals. An integrated platform provides a single hub for incident tracking, corrective action management, and data analysis. This improves response times, helps uncover root causes, and allows proactive risk reduction, ultimately reducing injuries, property damage, and regulatory exposure.

ROI comes from both cost savings and avoided risks. By reducing waste mismanagement, eliminating manual reporting inefficiencies, and consolidating compliance tracking, companies can save hundreds of thousands annually. In addition, better visibility into incidents and product quality issues can directly lower the financial impact of safety failures.

Chemical operations often span multiple sites with evolving regulatory and operational needs. Scalable, configurable platforms allow companies to start with critical modules, such as incident management or audits, and expand to areas like supplier management, sustainability reporting, or quality assurance. Flexibility ensures the system grows in step with the business rather than becoming obsolete.

Expand your EHSQ knowledge with these featured resources

EGUIDE

Now more than ever – in terms of cost and the impact on the environment and ESG reporting...

ON-DEMAND WEBINAR

Today’s business problems require strong, integrated solutions. In EHS and quality, those solutions can come from building on the common...

ON-DEMAND WEBINAR

Every organization wants to provide innovative products and services that meet customer requirements and support the business strategy...

Interested in learning more?

Schedule a free 30 minute session with one of our experts and

explore how Intelex Software can transform your business.

1 877 932 3747

1 877 932 3747