Unify Safety, Quality, and Sustainability Across Your Manufacturing Operations

Simplify the way you track, analyze, and report with Intelex’s 40+ out-of-the-box applications for manufacturing.

Trusted by Leading Manufacturing Organizations Around the World

Intelex's Safety Software Solutions for Streamlined

Compliance and Enhanced Risk Mitigation

Explore customized solutions for incident management, audits and training,

ensuring seamless compliance and enhanced risk mitigation in manufacturing.

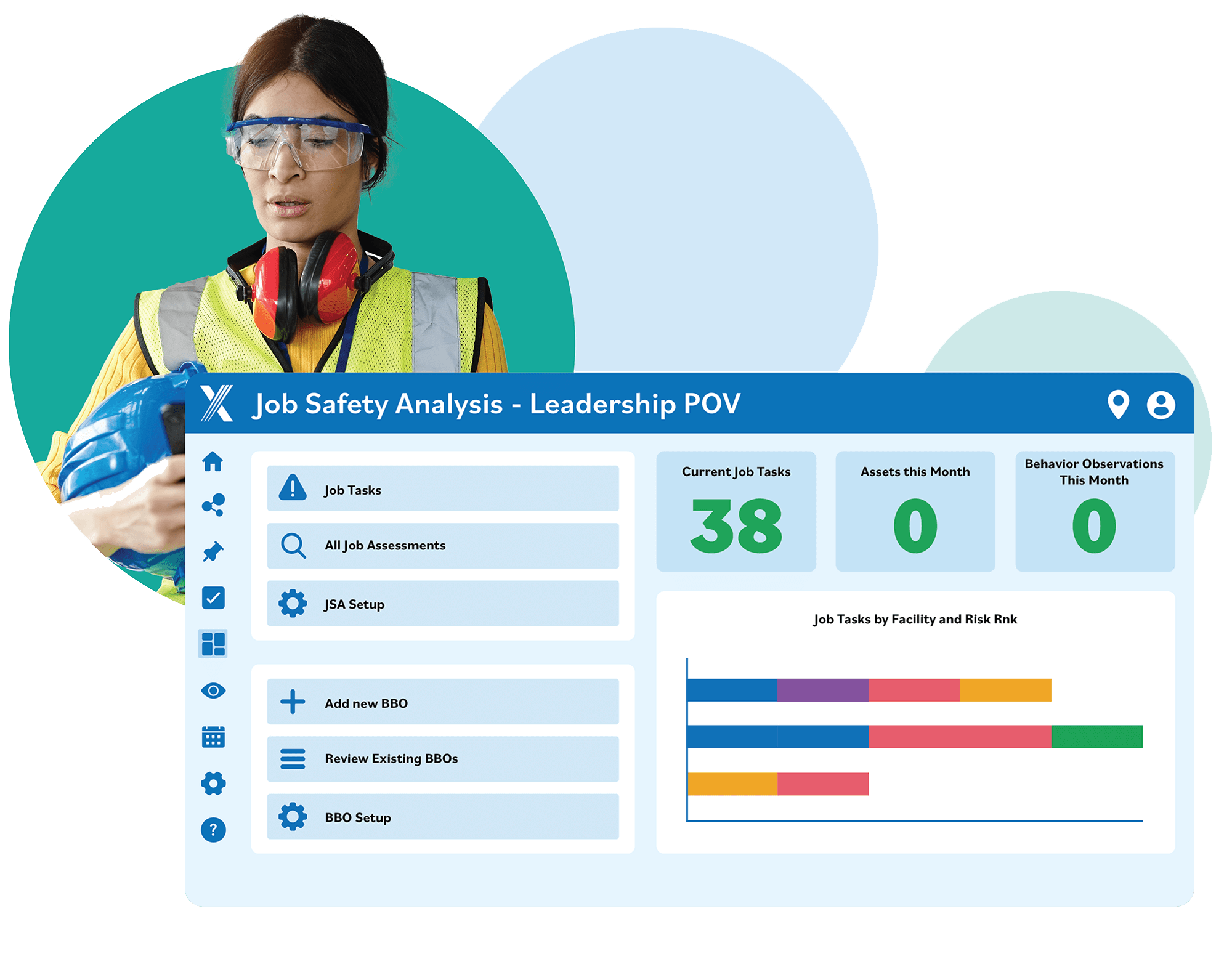

Empower Leaders to Act

Leaders can make faster, more confident decisions with configurable dashboards and site-level reporting that delivers visibility into equipment safety, floor risks, and compliance exposure.

Use leading indicators like near-misses, observations, training status, process hazard analyses and audit/inspection findings for better decision making at the plant level.

From frontline workers to operations leadership, Intelex engages every level with role-based dashboards, bulletins, corrective action tracking, and real-time alerts. Workers see their input drive real change — boosting trust, ownership, and engagement.

Bring EHSQ metrics into executive discussions. Intelex helps connect safety and sustainability to business priorities like cost, throughput, and ESG goals so your program gets visibility and support.

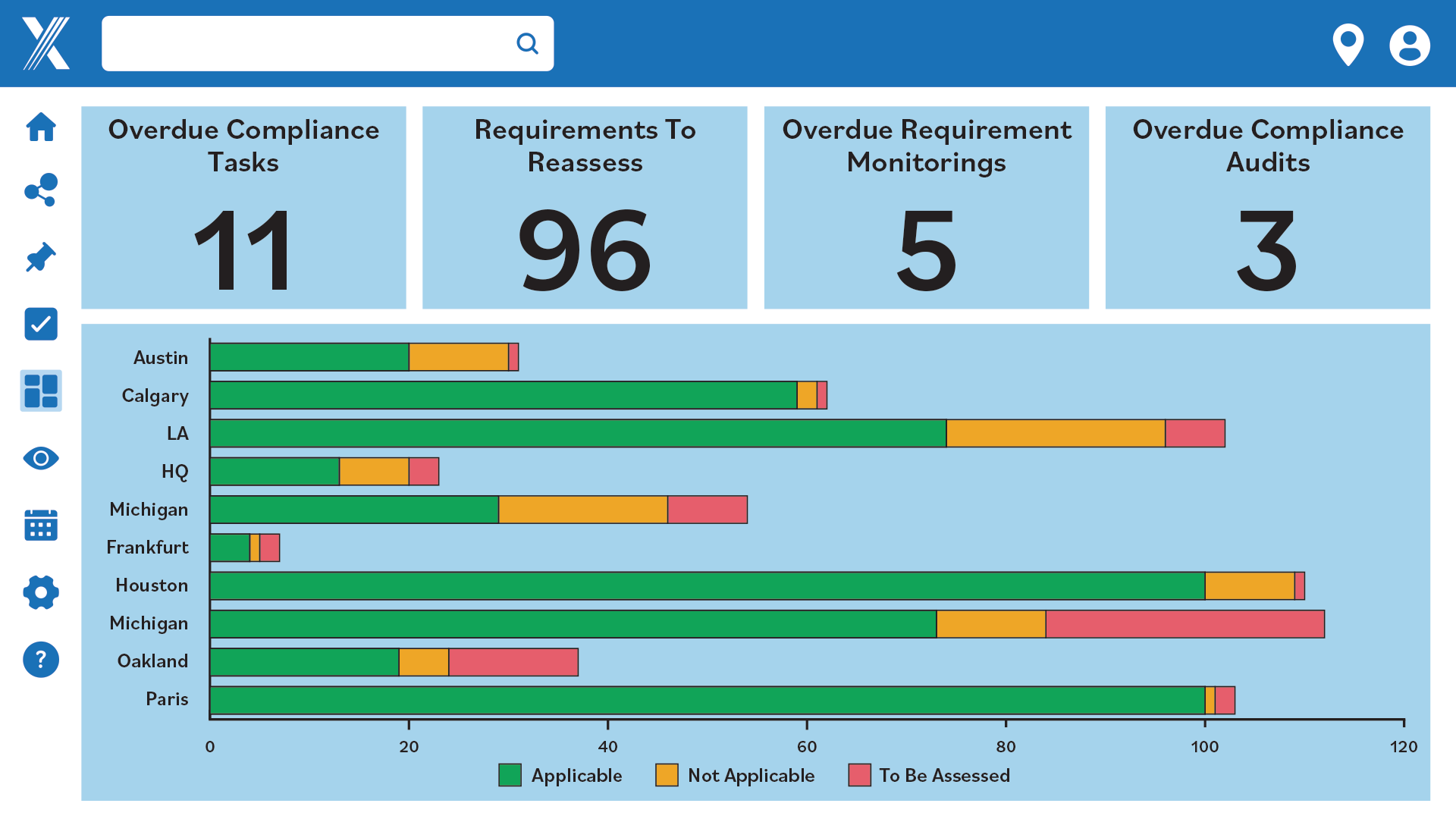

Meet Every Regulatory Requirement

Teams can easily stay on top of requirements and demonstrate conformance with centralized activities across compliance tracking, action management, and task management.

Every audit and inspection finding is automatically assigned as owner, tracked to closure, and monitored in one system.

Have confidence that every site is safe and compliant because Intelex helps standardize processes across all facilities.

Build a Skilled, Engaged Workforce

Frontline employees can easily report hazards and complete inspections on the spot with mobile tools, giving you more data, faster action, and stronger participation.

Deliver role-specific training content and track completion to ensure compliance and help employees gain the skills and confidence to work safely and efficiently.

Line workers, supervisors, and contractors can easily report issues and turn shop-floor insights into plant-wide improvements.

Control Hazards Across Operations

Connect incident data with JSAs, observations, and audits to identify trends before they lead to downtime or injury. Intelex helps you act on leading indicators and drive site-specific and global improvements.

Real-time risk scoring ensures the most urgent hazards rise to the top. With a clear, consistent process, you can make informed decisions and address threats before they escalate.

Create centralized risk registries and link risk data across programs like JSA and incident management.

Capture, Track, and Learn From Incidents

Every event is submitted and routed to the right people in a timely manner with Intelex’s standardized and simplified reporting.

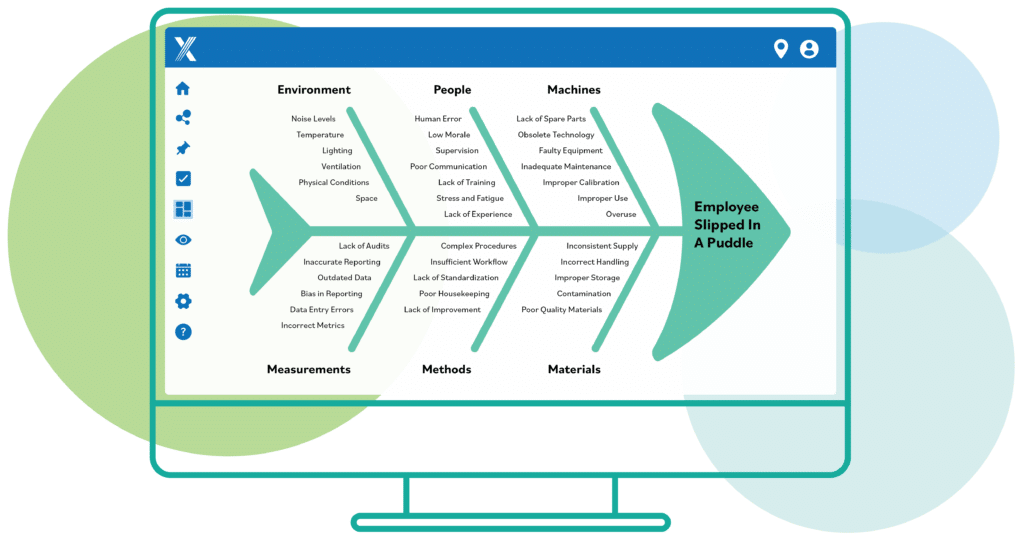

Ensure root causes are found and actions are taken with structured tools like 5-Whys and fishbone diagrams.

Easily compare leading and lagging indicators and target improvement efforts by connecting incident data with observations, JSAs, risks, and inspections.

Integrates With Your Existing Tech Stack

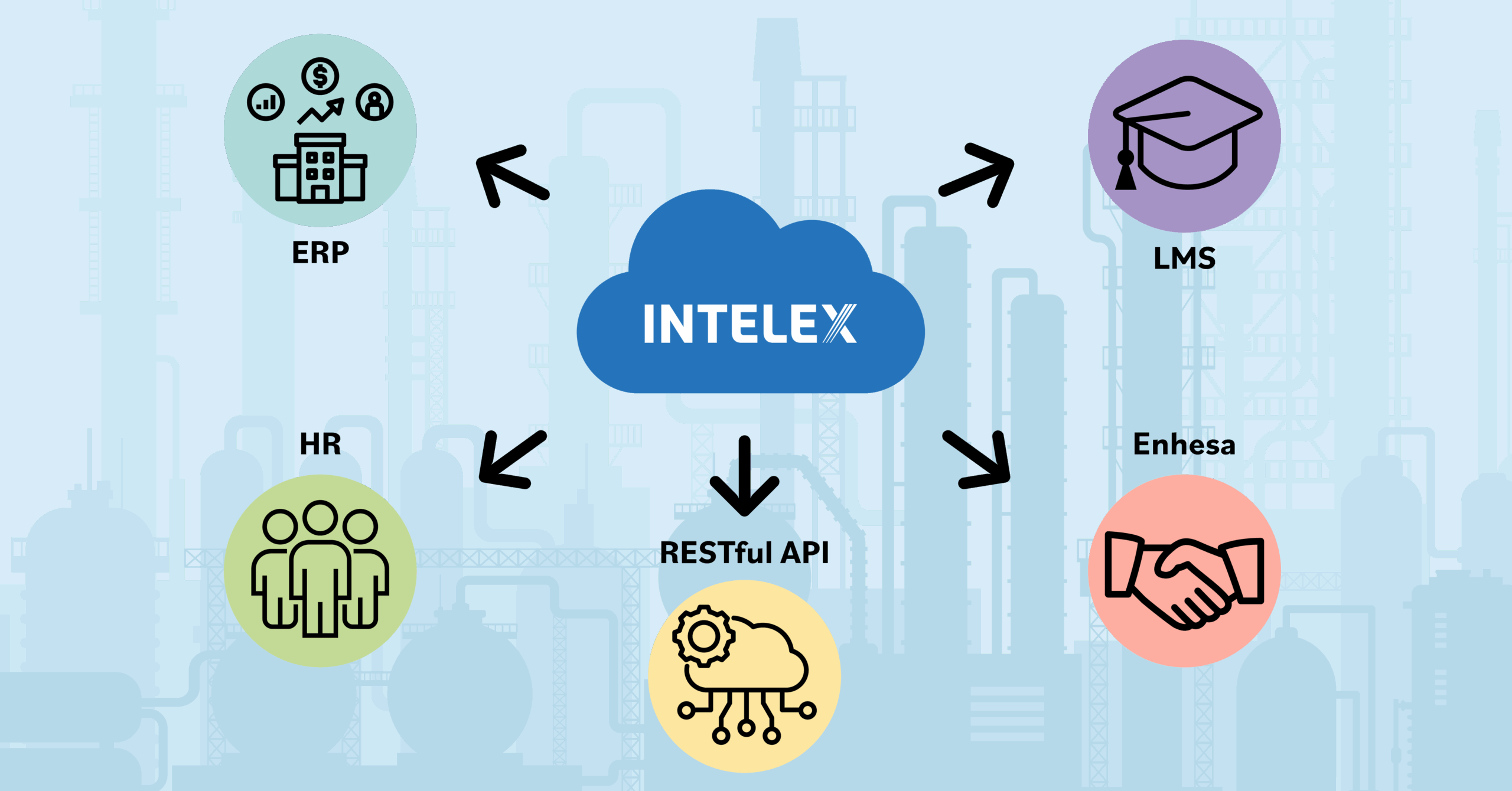

Easily connect Intelex to your ERP, HR, LMS, and reporting tools with minimal IT effort. You can also expand your capabilities through partners like Enhesa and TapRooT®, making it easy to scale compliance, investigations, and risk management across the business.

Management Systems That Fit Your Workflow

You shouldn’t have to change your process to fit the software. Intelex lets you keep what works and improve what doesn’t so your team can move faster. Build on your existing processes with flexible tools and best-practice templates — while meeting the requirements of ANSI, ISO, SEMI, and more.

Safety Management Software for Manufacturing

Gain real-time visibility across sites, reduce incidents, drive accountability to make safety a competitive advantage.

Quality Management Software for Manufacturing

Simplify the full PDCA cycle in one connected platform. Catch defects early, close the loop fast, and reduce rework and cost of poor quality.

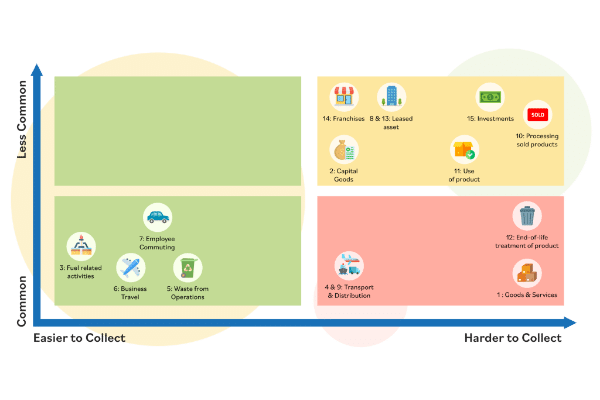

Environmental Management Software for Manufacturing

Track permits, emissions, and ESG data in one place — supporting CSRD, Scope 1-3, and site-level compliance.

Watch a Demo of Intelex’s Safety and Quality Management Software for Manufacturing

See how our cloud-based platform helps manufacturing teams simplify safety processes, drive compliance, and build a resilient safety culture.

Manufacturing Safety and Quality Software Solution playlist

Discover how SGS successfully improved their

safety management system with Intelex solutions

Frequently Asked Questions

Safety and Quality Management Software is a solution to systematically handle safety and quality processes. It includes features like incident management, risk assessment and advanced analytics to enhance overall performance, ensure regulatory compliance and sustain a culture of continuous improvement.

Intelex Safety and Quality Management software is crucial for manufacturing organizations, offering streamlined incident management, compliance assurance, risk mitigation and quality control. It boosts operational efficiency and cultivates a culture of continuous improvement, ensuring robust safety and quality standards.

Yes, Intelex Manufacturing Safety and Quality Management Software offers configurable features, allowing adaptation to specific workflows, forms and reporting structures.

Yes, Intelex Manufacturing Safety and Quality Management Software is designed to accommodate updates and modifications to regulatory requirements, ensuring ongoing compliance for manufacturing organizations.

Explore Intelex Resources for Safety and

Quality Excellence in Manufacturing

Interested in learning more?

Schedule a free 30 minute session with one of our experts and

explore how Intelex Software can transform your business.

1 877 932 3747

1 877 932 3747