How Kloeckner Metals Achieved a 55% Reduction in OSHA Recordables with Intelex

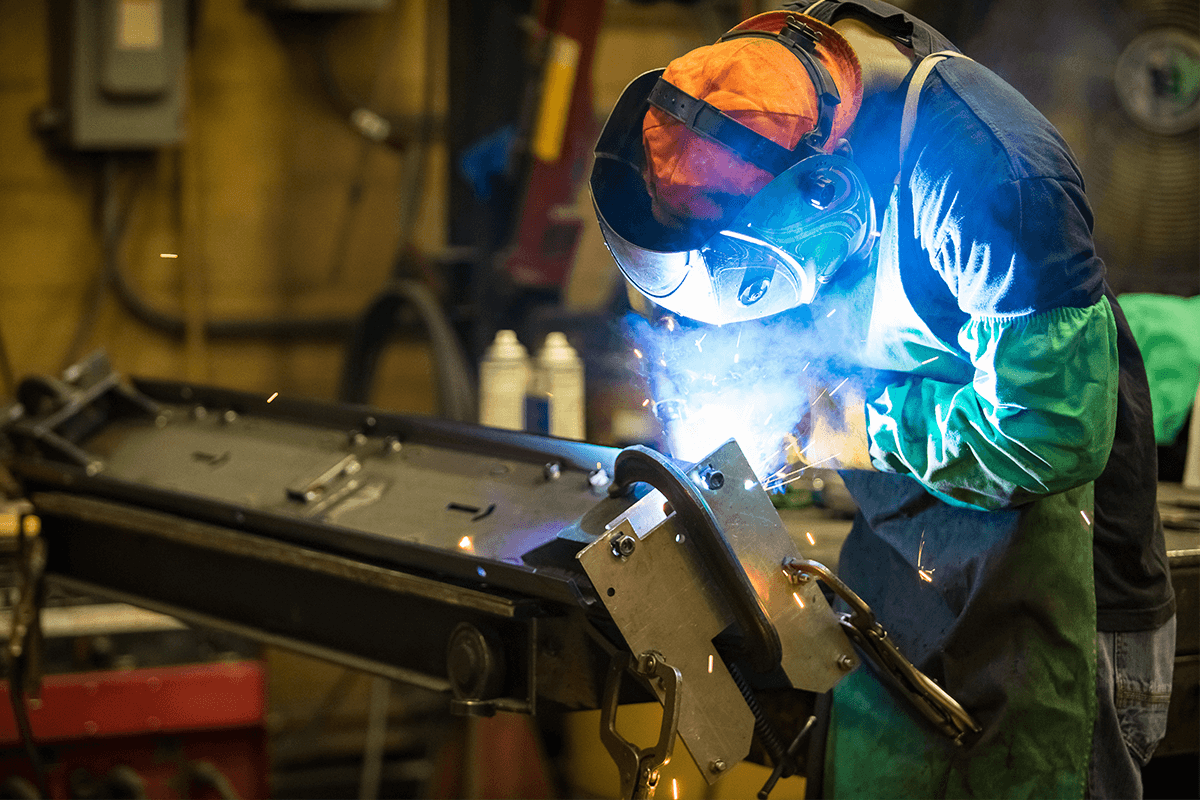

Kloeckner Metals Corporation is one of the largest metals manufacturing, supply, and service companies in North America. With 55+ branches in the United States and Mexico, and over 120 worldwide, Kloeckner is focused on using technology to make its supply and service chain faster and more efficient.

Impact

- 55% reduction in OSHA recordables.

- 43% reduction in restricted duty cases.

- 62% decrease in lost-time injuries.

- 61% increase in employee engagement in safety activities.

- 26% improvement in employees feeling empowered to take action.

Outcome

Intelex helped Kloeckner Metals unify its EHS systems into a single integrated platform, eliminating inefficiencies, automating injury and claims reporting, and driving higher employee engagement in safety activities.

The Challenge for Kloeckner Metals

As a company focused on digital transformation, Kloeckner needed to modernize its EHS systems to align with its broader automation strategy. However, its EHS processes were fragmented across multiple, disconnected systems, making it difficult to track incidents, conduct safety meetings, perform job hazard analyses, and manage corrective actions.

- Siloed EHS systems created inefficiencies and manual redundancies.

- Lack of real-time visibility into safety performance and risks.

- Time-consuming manual claims reporting added administrative burden.

- No centralized data for ESG tracking, making compliance difficult.

Kloeckner needed a single, scalable solution to enhance safety, streamline reporting, and drive a culture of proactive risk management.

"After the implementations of Intelex, we saw significant improvements compared to metrics from 2018, including a 55% improvement in OSHA recordables, 43% improvement in restricted duty cases, and a 62% improvement in lost-time injury cases."

Rick Gruca, Vice President of Safety, Health, Environmental & Sustainability, Kloeckner Metals

“In 2019, we saw a 61 percent improvement in employee involvement in safety activities and a 26 percent improvement in employees feeling empowered to take action in safety.”

Rick Gruca, Vice President of Safety, Health, Environmental & Sustainability, Kloeckner Metals

"We also have used the system to help track and communicate both close calls (near misses) and safety observations, which has helped tremendously in increasing employee engagement."

Rick Gruca, Vice President of Safety, Health, Environmental & Sustainability, Kloeckner Metals

How Intelex Helped Kloeckner Metals

Kloeckner Metals partnered with Intelex to unify its EHS systems into a single, integrated platform, eliminating inefficiencies and automating key safety and compliance processes.

With Intelex EHS Incident Management, Kloeckner automated injury and auto claims reporting, cutting manual work, and speeding up processing.

To boost engagement, the company launched a Close Call and Safety Observations program. Weekly reports now go to leadership, increasing accountability and risk prevention.

Beyond EHS, Kloeckner expanded Intelex’s capabilities to digitize its Capital Expenditure (CapEx) approval process, which was previously handled through manual email exchanges. This new workflow reduced approval times, ensured compliance, and provided an auditable digital trail for every request.

Additionally, automated Safety KPI reports—generated through Intelex—allowed leadership to monitor both leading and lagging indicators in real time, helping the company make data-driven safety and ESG decisions.

1 877 932 3747

1 877 932 3747