Safety and Quality Software Applications for Manufacturing

Intelex’s suite of customizable Safety and Quality Management applications help streamline manufacturing processes, from production to compliance. Identify, assess and mitigate risks, ensuring a safer work environment. With on-site data collection, real-time monitoring and excellent customer support, we optimize efficiency, reduce paperwork and drive cost savings for your manufacturing organization.

- Risk Mitigation for a Safer Workplace: Identify, assess and mitigate risks in manufacturing projects, contributing to a safer workplace.

- Mobile-Enabled Flexibility: Enable on-site data collection, incident reporting and real-time monitoring through mobile devices, enhancing flexibility and responsiveness.

- Comprehensive Support: Benefit from ongoing customer support and updates to ensure a smooth implementation and optimal utilization of Intelex software.

- Operational Efficiency and Cost Savings: Enhance overall efficiency, reduce paperwork and contribute to cost savings in your manufacturing organization.

- Safety

- Quality

Training Management Software

Training Management Software for manufacturing ensures streamlined training, certification tracking and skill development. It optimizes productivity, compliance and proficiency, contributing to a more skilled and efficient manufacturing workforce.

- Safety

- Quality

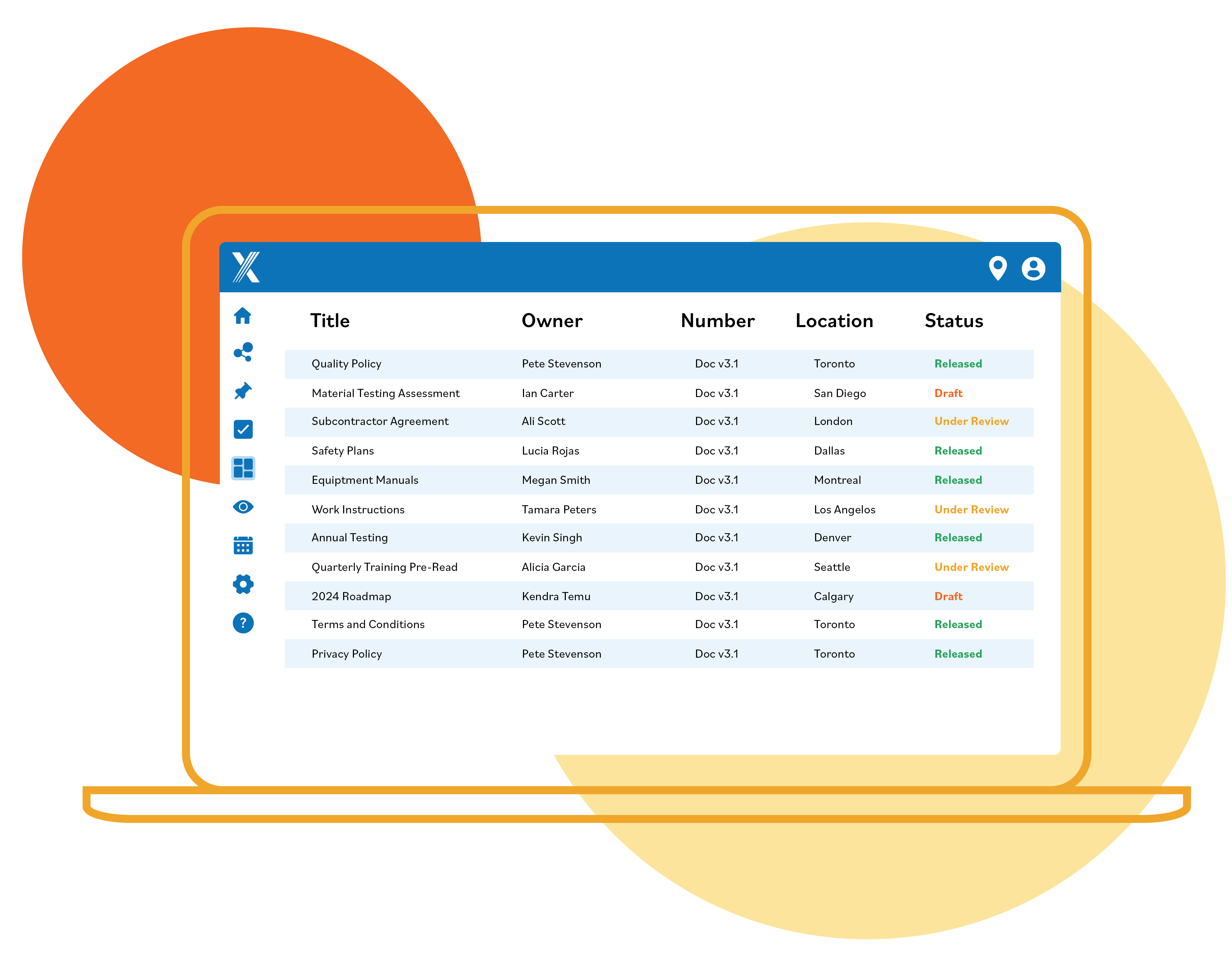

Document Control Software

Document Control Software ensures precision in document creation, approval and distribution, guaranteeing that all stakeholders access the latest and approved versions. By maintaining a centralized and organized platform, it enhances compliance, mitigates risks and streamlines documentation processes.

- Safety

- Quality

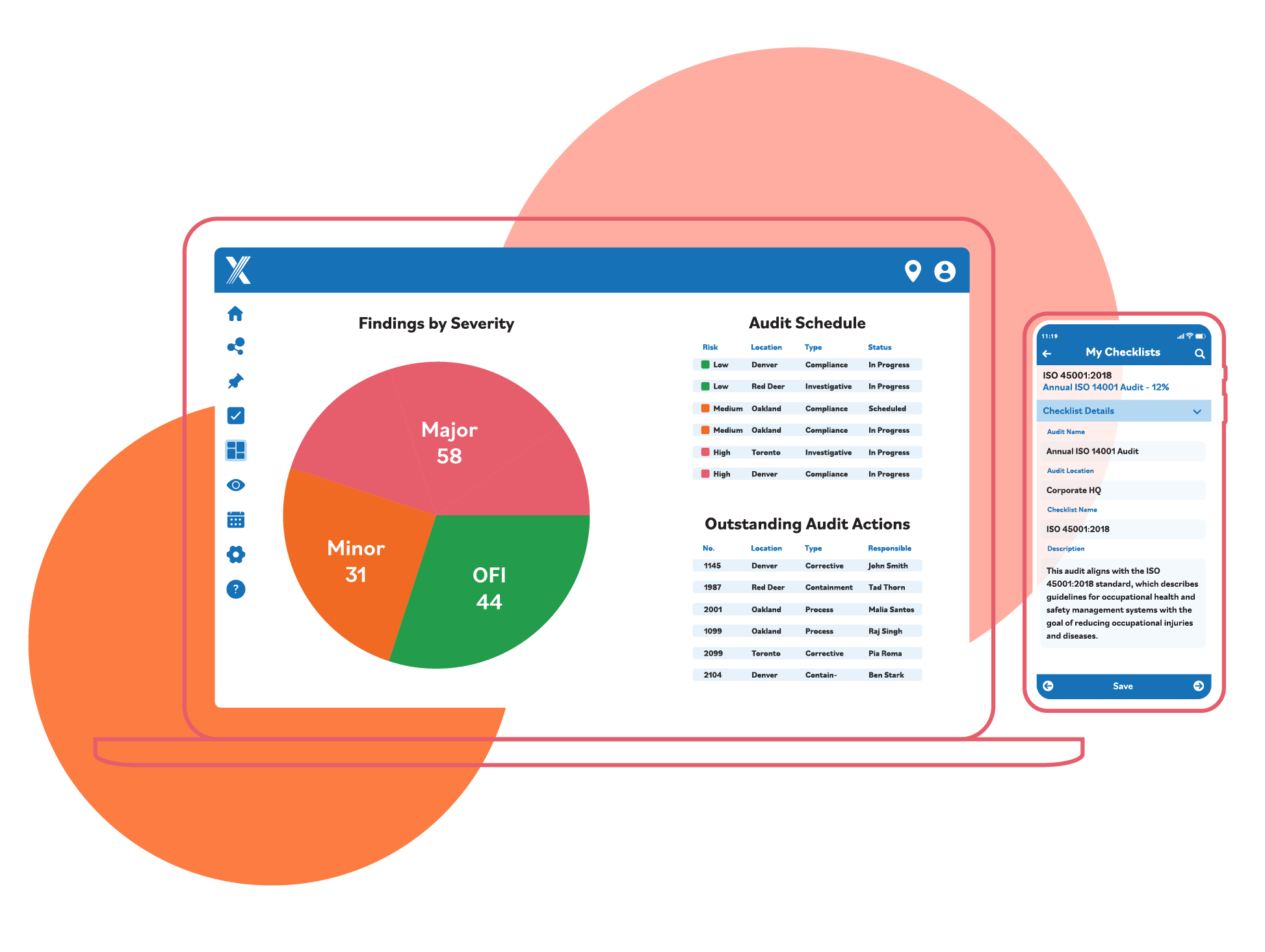

Audit Management Software

Audit Management Software provides a systematic and efficient approach to conducting and managing audits, ensuring adherence to industry standards and regulations. With customizable workflows and real-time tracking, it empowers manufacturing organizations to enhance transparency, identify areas for improvement and maintain rigorous compliance standards.

- Safety

- Quality

Nonconformance Management Software

Nonconformance Management Software enables manufacturing organizations to quickly identify, assess and address deviations from quality and safety standards. Through customizable workflows and real-time tracking, it streamlines the resolution process, ensuring prompt corrective actions and continuous improvement in safety and product quality.

- Safety

Safety Inspection Management Software

Safety Inspection software streamlines and enhances workplace safety by facilitating inspections and managing compliance. Through a mobile app, you can easily perform inspections on the go, ensuring real-time monitoring and efficient tracking of safety measures across diverse work locations.

- Safety

- Quality

Near Miss Reporting Software

Near Miss Reporting software is a tool designed to enhance workplace safety by allowing workers to promptly and efficiently report incidents where an accident almost occurred. This software captures near misses, analyzes patterns and facilitates corrective actions, promoting a proactive safety culture within your organization.

- Quality

Supplier Management Software

Supplier Management software streamlines and optimizes the entire procurement process by providing a centralized platform to monitor, evaluate and collaborate with suppliers. This software enhances supply chain efficiency, ensuring seamless communication, quality control and strategic collaboration to meet manufacturing objectives.

- Safety

- Quality

Risk Management Software

Risk Management software is a comprehensive solution designed to identify, assess and mitigate potential risks. By utilizing advanced analytics and tracking capabilities, this software empowers manufacturing organizations to proactively manage uncertainties, enhance decision-making and safeguard against incidents, promoting overall resilience and sustainability.

- Safety

Job Safety Analysis Software

Job Safety Analysis software is a powerful tool that systematically evaluates and mitigates workplace risks by breaking down tasks into detailed steps, identifying potential hazards and recommending safety measures. This software enhances safety by providing a structured framework for manufacturing organizations to analyze and address potential job-related risks.

- Quality

Customer Complaint Management Software

Customer Complaint Management software facilitates efficient tracking, resolution and analysis of customer concerns, ensuring timely responses and improved customer satisfaction. This software streamlines communication, allowing manufacturing organizations to address issues promptly, enhance product quality and maintain positive customer relationships.

- Safety

Safety Observations Management Software

Safety Observations Management software empowers workers to report and document real-time safety concerns and observations in the workplace. By encouraging a proactive safety culture, this software enables quick identification of potential hazards, facilitates timely interventions and contributes to overall safety performance.

- Safety

Incident Management Software

Incident Managment software provides an efficient system for recording, tracking and analyzing workplace incidents, accidents or near misses. This software enhances safety by enabling prompt reporting, thorough investigations and implementation of corrective actions, ultimately contributing to a safer working environment in the manufacturing sector.

- Safety

- Quality

CAPA Software

Corrective and Preventive Action (CAPA) software is designed to identify, address and prevent issues in safety protocols and production processes. This specialized software streamlines the CAPA process by facilitating the documentation of incidents, root cause analysis and the implementation of corrective measures, ensuring continuous improvement, quality control and compliance in manufacturing operations.

- Quality

Management of Change Software

Management of Change (MOC) software is a specialized tool that facilitates and streamlines the process of implementing changes within an organization. It ensures a systematic approach to evaluating, approving and tracking modifications to processes, systems or equipment, enhancing efficiency and reducing the risk of operational disruptions.

- Safety

- Quality

Permit Management Software

Permit Management software provides a centralized platform for efficiently managing and tracking various permits required for production and safety. This software ensures compliance with regulatory requirements, streamlining the permit application and approval process and enhancing overall operational efficiency in the manufacturing industry.

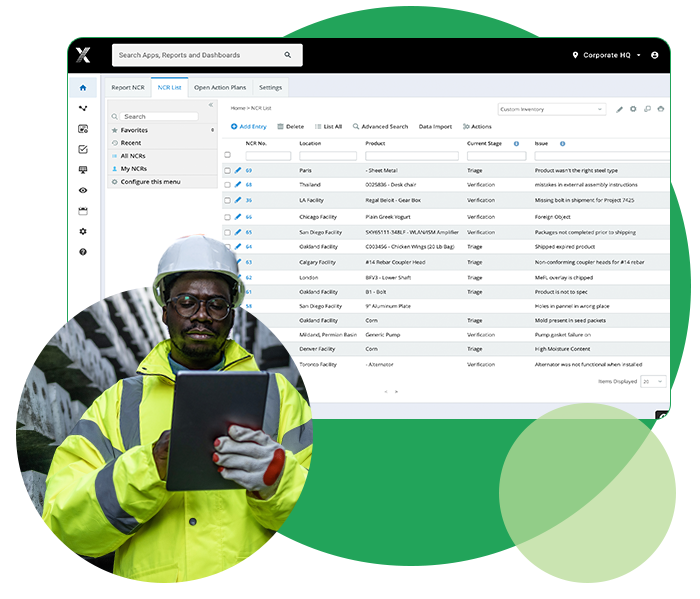

What is Nonconformance Reporting Software?

Nonconformance Reporting software is a versatile tool that addresses deviations from quality and safety standards. It is a solution for reporting, investigating and resolving instances where products, processes or systems fail to meet established requirements. It ensures that manufacturing organizations can maintain high standards across their operations, minimize risks and create a culture of continuous improvement in both quality and safety practices.

How does it benefit the manufacturing industry?

Intelex Nonconformance Reporting software significantly benefits the manufacturing industry by rapidly identifying and addressing quality and safety deviations. It streamlines the reporting process, enabling quick response to nonconformities, reducing downtime and preventing recurrence. This proactive approach enhances overall product quality, ensures compliance with safety regulations and encourages a culture of continuous improvement, ultimately contributing to increased operational efficiency and customer satisfaction.Why should you choose Intelex Nonconformance Management software?

Here are several reasons for choosing Intelex Nonconformance Reporting Software:- Streamlined Resolution: Enables prompt identification and resolution of quality and safety issues, minimizing production disruptions and reducing the likelihood of defects reaching the market.

- Systematic Root Cause Analysis: Facilitates a structured approach to investigating nonconformances, helping manufacturing professionals identify root causes and implement effective corrective actions to prevent future occurrences.

- Regulatory Compliance: Ensures adherence to quality and safety regulations by providing a centralized platform for tracking, documenting and addressing nonconformances, reducing the risk of regulatory penalties and fines.

- Enhanced Product Quality: Contributes to improved product quality and customer satisfaction by addressing nonconformances in real-time, resulting in higher-quality products and a positive impact on brand reputation in the manufacturing industry.

What is Training Management Software?

Training Management software streamlines and optimizes the entire training process within an organization. It facilitates the creation, tracking and management of training programs, ensuring efficient deployment, assessment and documentation of learning activities to enhance skill development and compliance across the workforce.

How does it benefit the manufacturing industry?

Intelex Training Management software centralizes and automates training processes. It ensures that workers receive timely and relevant training, enhancing their skills and productivity. Intelex software tracks certifications and compliance requirements, ensuring regulatory adherence, while also promoting a safer work environment. Additionally, it enables manufacturers to identify areas for improvement and adapt quickly to evolving industry standards.Why should you choose Intelex Training Management Software?

Choosing Intelex Training Management Software offers several advantages:- Regulatory Compliance: Stay compliant with industry regulations by tracking and managing certifications, keeping workers up to date with the latest standards and safety protocols.

- Centralized Tracking and Reporting: Allows for centralized tracking of training records and generates insightful reports, facilitating easy monitoring of workforce development, identifying gaps and ensuring accountability.

- Enhanced Efficiency and Productivity: With streamlined processes and automated workflows, Intelex Training Management Software contributes to increased operational efficiency and productivity within manufacturing companies, ultimately driving overall success.

- User-Friendly Interface: An intuitive and user-friendly interface makes it easy to navigate and implement training programs seamlessly. This enhances worker engagement and encourages active participation in training initiatives.

What is Supplier Management Software?

Supplier Management software helps to streamline and optimize the processes involved in managing relationships with suppliers. It encompasses functionalities such as supplier onboarding, performance evaluation and collaboration, providing a centralized platform for manufacturing organizations to efficiently monitor and enhance the entire supplier lifecycle, ensuring transparency, compliance and improved collaboration with key partners in the supply chain.

How does it benefit the manufacturing industry?

Intelex Supplier Management software streamlines vendor onboarding, enhances collaboration and ensures consistent adherence to quality standards. It optimizes procurement processes, negotiates favorable terms and identifies cost-saving opportunities, enhancing overall cost efficiency in manufacturing operations.Why should you choose Intelex Supplier Management software?

Intelex Supplier Management software brings several benefits to the manufacturing industry:- Efficient Vendor Onboarding: Streamlines the onboarding process for new suppliers, ensuring a quicker integration into the manufacturing supply chain and reducing time-to-market for new products.

- Enhanced Collaboration: Facilitates improved communication and collaboration with suppliers, improving partnerships and allowing for real-time information exchange, which is crucial for seamless production processes.

- Risk Mitigation: Identifies and mitigates potential risks within the supply chain by providing tools for assessing and monitoring supplier compliance, reliability and financial stability, thereby minimizing disruptions in the manufacturing process.

- Cost Efficiency: Optimizes procurement processes, negotiates better terms and identifies cost-saving opportunities through data-driven insights, contributing to increased cost efficiency in the manufacturing operations.

What is Safety Observations Management Software?

Safety Observations Management software facilitates the reporting and analysis of safety observations in the workplace. It provides a centralized platform for workers to document and communicate safety concerns, promoting a proactive safety culture. The software enhances incident prevention by enabling organizations to track and address potential hazards promptly, encouraging a safer work environment.

How does it benefit the manufacturing industry?

Intelex Safety observations Management software, which features a mobile app that operates both online and offline, promotes a proactive safety culture by allowing workers to report concerns in real-time, enabling quick hazard mitigation and generating executive-level insights for efficient incident prevention. A mobile app also enhances communication, collaboration and overall workplace safety in manufacturing environments, ensuring a safer and more resilient operational landscape.Why should you choose Intelex Safety Observations Management Software?

Choosing Intelex for Safety Observations Management software presents compelling advantages such as:- Proactive Safety Culture: Facilitates real-time reporting of safety concerns, encouraging workers to proactively identify hazards.

- Mobile Accessibility: The mobile app, functional both online and offline, allows workers to report observations in real-time, even in areas with limited connectivity.

- Timely Hazard Mitigation: Enables quick tracking and addressing of potential hazards, reducing the risk of incidents and enhancing overall workplace safety.

- Efficient Incident Prevention: Generates comprehensive analyses of observations for preventive measures, contributing to a safer manufacturing environment and minimizing operational disruptions.

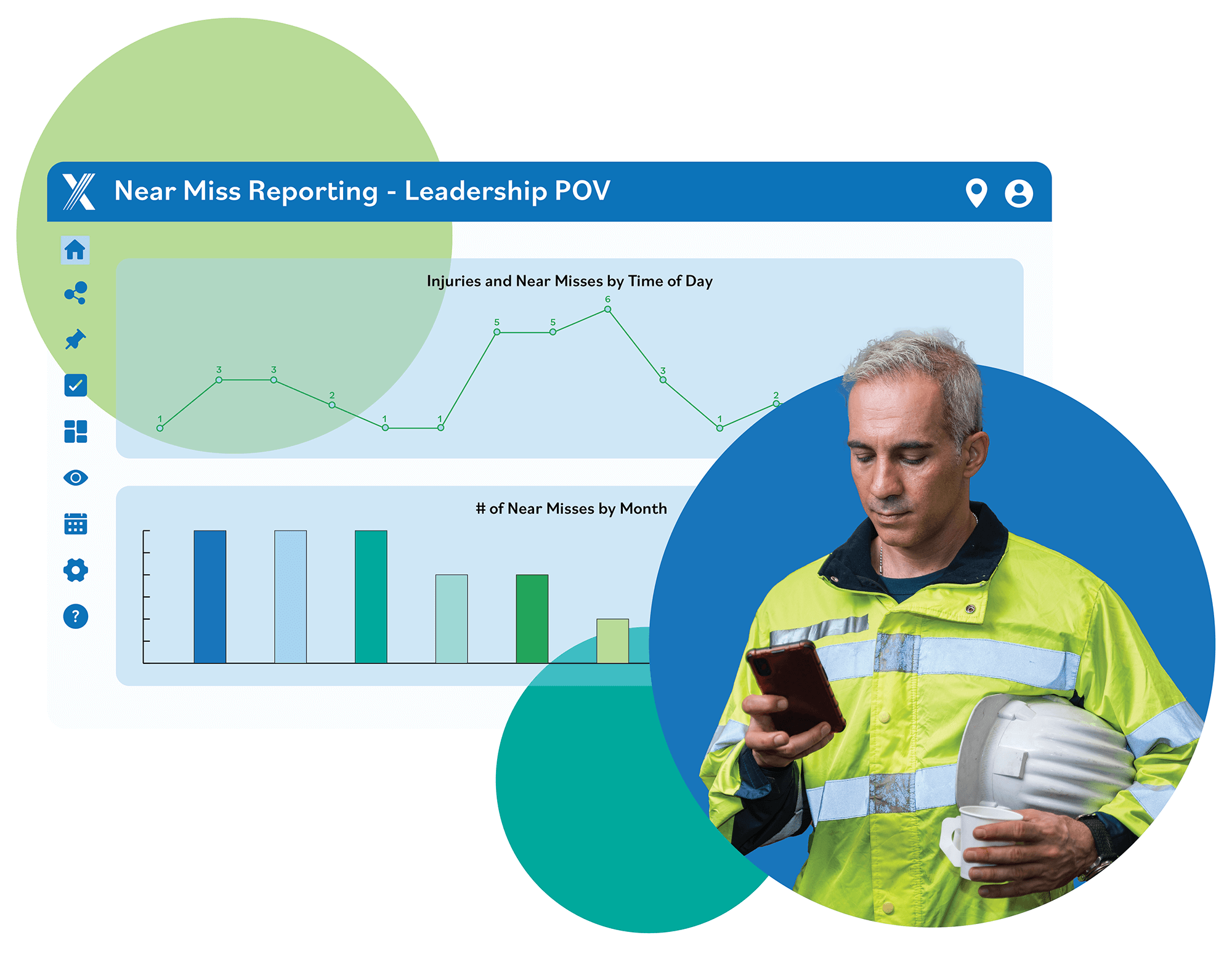

What is Near Miss Reporting Software?

Near Miss Reporting software helps to capture and analyze incidents where an unplanned event almost resulted in an injury, damage or loss. It allows organizations to systematically collect data on potential hazards, providing valuable insights to proactively address safety concerns, improve preventive measures and create a safer workplace by learning from incidents that could have led to more severe consequences.

How does it benefit the manufacturing industry?

By capturing and analyzing incidents that narrowly avoid harm, Intelex Near Miss Reporting software allows manufacturing organizations to implement preventive measures, reducing the risk of injuries and damage. It enhances operational efficiency by addressing potential issues before they escalate, contributing to a safer work environment and ensuring compliance with safety regulations.Why should you choose Intelex Near Miss Reporting Software?

Here are key ways in which Intelex Near Miss Reporting software is advantageous:- User-Friendly Interface: Offers an intuitive and user-friendly interface, making it easy for workers at all levels to report near misses efficiently.

- Mobile Accessibility: Allows workers to report near misses on the go, ensuring real-time data capture and enhancing the timeliness of corrective actions.

- Customizable Solutions: The software provides customizable reporting forms and workflows, allowing manufacturing companies to tailor the system to their specific needs and industry requirements.

- Advanced Analytics: Includes powerful analytical tools that enable manufacturing companies to analyze near miss data comprehensively, extracting valuable insights for continuous improvement.

What is Incident Management Software?

Incident Management software streamlines the reporting, tracking and management of workplace incidents. It provides a centralized platform for workers to document and communicate incidents, facilitating prompt analysis, corrective actions and preventive measures. This software promotes a proactive safety culture within manufacturing organizations, ensuring a timely and effective response to incidents for continuous improvement in workplace safety.

How does it benefit the manufacturing industry?

Intelex Incident Management software benefits the manufacturing industry by facilitating quick responses to incidents and minimizing production downtime. It encourages a proactive safety culture by encouraging prompt reporting, ensuring compliance with regulations and promoting continuous improvement in safety protocols. The software streamlines communication, enhancing collaboration among stakeholders for effective incident resolution and long-term workplace safety.Why should you choose Intelex Incident Management software?

Here are several reasons to choose Intelex Incident Management Software:- Customizable Form Generation: Allows teams to generate industry-specific forms, ensuring the capture of critical details relevant to the unique challenges and processes in manufacturing environments.

- Mobile and Offline Reporting: With a dedicated mobile app, manufacturing personnel can report incidents in real-time, directly from the production floor.

- Smart Task Management: Intelligent workflows can be tailored to manufacturing processes, scheduling tasks and setting due dates for incident resolution, ensuring that they are efficiently managed and completed on time.

- Visualize Key Safety Metrics: Gain intelligent insights into incident trends, allowing you to track and improve safety performance, prioritize resource allocation and maintain a safer workplace.

What is CAPA Software?

Corrective and Preventive Action (CAPA) software is designed to manage and streamline the process of addressing and preventing issues. It systematically identifies and resolves problems through corrective actions while implementing preventive measures to avoid the recurrence of similar issues, ensuring continuous improvement and adherence to safety and quality standards.

How does it benefit the manufacturing industry?

Intelex Corrective and Preventive Action (CAPA) software streamlines issue resolutions, implements preventive measures, ensures compliance and promotes a culture of continuous improvement. With advanced analytics, it facilitates data-driven decision-making, enhancing efficiency and reducing risks. The software's automation and accountability features contribute to timely issue resolution, maintaining consistent product quality and customer satisfaction.Why should you choose Intelex CAPA Software?

There are many reasons to choose Intelex CAPA software, including:- Efficient Issue Resolution: Streamlines the identification, investigation and resolution of quality and safety issues, reducing downtime and maintaining consistent product quality.

- Configurability: Tailors workflows and forms to specific organizational needs, ensuring flexibility and adaptability to evolving industry requirements.

- Analytics and Reporting: Provides advanced analytical tools, allowing you to derive meaningful insights from CAPA data for informed decision-making and continuous improvement efforts.

- Compliance Management: Supports adherence to industry standards and regulations by documenting and tracking corrective and preventive actions, ensuring transparency and facilitating audit trails.

What is Risk Management Software?

Risk Management software is designed to identify, assess and mitigate potential risks. It provides a centralized platform for systematic risk analysis, monitoring and implementation of preventive measures, helping manufacturing companies enhance decision-making and ensure compliance.

How does it benefit the manufacturing industry?

Intelex Risk Management software enables early identification and mitigation of potential risks. It enhances operational resilience, ensures compliance with regulations and optimizes resource allocation. By creating a culture of continuous improvement, the software contributes to proactive risk management and ongoing enhancement of manufacturing operations.Why should you choose Intelex Risk Management Software?

Choosing Intelex Risk Management software offers several compelling advantages:- Proactive Risk Identification: Enables early identification and assessment of potential risks in manufacturing processes, allowing proactive measures to be implemented to prevent disruptions.

- Operational Resilience: Enhances the overall resilience of manufacturing operations by systematically addressing and mitigating risks, ensuring continuity and minimizing the impact of unforeseen incidents.

- Compliance Assurance: Facilitates adherence to regulatory requirements by providing a structured approach to identifying and managing risks related to compliance, reducing the likelihood of penalties or legal issues.

- Resource Optimization: Optimizes resource allocation by prioritizing and addressing high-impact risks, allowing manufacturing organizations to allocate resources efficiently and focus on areas critical to their success.

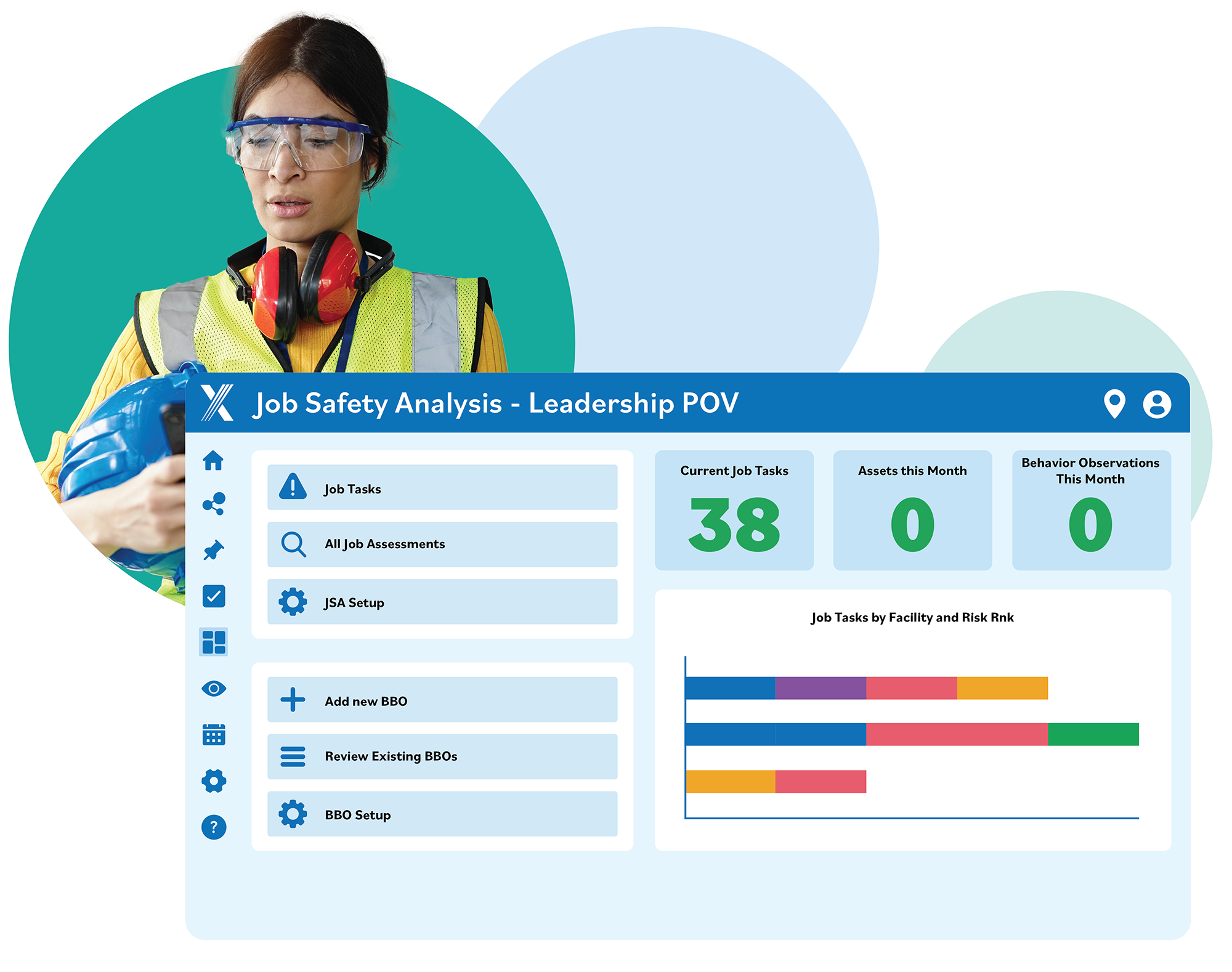

What is Job Safety Analysis Software?

Job Safety Analysis software helps to systematically evaluate and mitigate workplace risks by breaking down tasks into detailed steps. It allows for the identification of potential hazards, recommends safety measures and promotes a proactive safety culture, ensuring a safer workplace by empowering organizations to analyze and address potential job-related risks promptly.

How does it benefit the manufacturing industry?

Intelex Job Safety Analysis software is a customizable, efficient safety management tool that streamlines risk assessment, identifies hazards and recommends safety measures. With advanced analytics and insights, Intelex promotes a safety-first culture, ensuring compliance and continuous improvement. The software's user-friendly interface makes it an ideal choice for manufacturing, promoting a safer work environment and enhancing overall occupational well-being.Why should you choose Intelex Job Safety Analysis Software?

Choosing Intelex Job Safety Analysis software offers distinct advantages:- Risk Mitigation: Systematically identifies and mitigates job-related risks, ensuring a safer work environment and reducing the likelihood of accidents on the manufacturing floor.

- Regulatory Compliance: Helps manufacturing companies comply with safety regulations by providing a structured approach to analyzing and addressing potential hazards, minimizing the risk of regulatory penalties.

- Operational Efficiency: Streamlines safety processes, enhancing overall operational efficiency by reducing downtime due to accidents and ensuring a smoother workflow.

- Continuous Improvement: Facilitates ongoing improvement in safety protocols through advanced analytics and reporting, creating a proactive safety culture and contributing to long-term worker well-being.

What is Document Control Software?

Document Control software manages the creation, revision, approval and distribution of documents within an organization. It ensures version control, tracks changes and enhances collaboration, promoting efficient document lifecycle management for improved compliance, consistency and overall organizational efficiency.

How does it benefit the manufacturing industry?

Intelex Document Control software offers benefits such as version control to maintain accuracy, compliance management for adherence to industry regulations and streamlined collaboration through centralized document storage. With quick information retrieval and a comprehensive audit trail, this software enhances efficiency, accountability and transparency in manufacturing processes, contributing to improved quality management and facilitating continuous improvement initiatives.Why should you choose Intelex Document Control Software?

Intelex Document Control software provides significant advantages to the manufacturing industry:- Version Control: Ensures that manufacturing documents, such as SOPs and work instructions, are consistently up to date, reducing the risk of errors and enhancing operational accuracy.

- Compliance Management: Helps manufacturing companies adhere to industry regulations and standards by maintaining a comprehensive record of document revisions, approvals and distribution, ensuring compliance with quality and safety requirements.

- Efficient Collaboration: Facilitates seamless collaboration among teams by centralizing document storage, allowing multiple users to access, edit and review documents simultaneously, enhancing communication and teamwork.

- Quick Retrieval of Information: Streamlines the retrieval of critical information by providing a centralized repository, reducing the time spent searching for documents and improving overall productivity on the manufacturing floor.

- Audit Trail and Accountability: Creates an audit trail of document changes, ensuring accountability and transparency in the manufacturing processes, which is crucial for quality management and continuous improvement initiatives.

What is Management of Change (MOC) Software?

Management of Change (MOC) software optimizes implementing modifications within an organization. It ensures a structured approach to evaluating, approving and tracking changes to processes, systems or equipment, promoting operational efficiency and minimizing risks associated with organizational changes. The software facilitates documentation, communication and compliance with industry standards, promoting a proactive and well-managed approach to organizational transformations.

How does it benefit the manufacturing industry?

Intelex Management of Change (MOC) software helps to minimize the risks associated with modifications, ensuring an efficient approach to evaluating and approving changes. By facilitating compliance, documentation and communication, it enhances operational efficiency, improves collaboration and establishes a clear audit trail. This software supports a culture of continuous improvement, enabling manufacturing companies to navigate organizational changes seamlessly while maintaining safety, compliance and productivity.Why should you choose Intelex MOC Software?

Intelex MOC software offers significant advantages, including:- Risk Mitigation: Ensures a systematic approach to evaluating and approving changes, minimizing the risk of disruptions, accidents or quality issues associated with modifications to manufacturing processes or equipment.

- Operational Efficiency: Streamlines the change management process, reducing downtime and enhancing overall operational efficiency by facilitating smooth transitions and minimizing the impact on production schedules.

- Compliance Assurance: Helps manufacturing companies comply with industry regulations and safety standards by documenting and tracking changes, ensuring that modifications adhere to established guidelines.

- Documentation and Communication: Facilitates comprehensive documentation of changes, improving communication across teams and ensuring that all stakeholders are informed about modifications to processes, equipment or systems.

- Collaboration: Enhances collaboration between different departments involved in the change process, promotoing a coordinated approach and reducing the likelihood of errors or oversights.

What is Safety Inspection Management Software?

Safety Inspection software streamlines and enhances the process of workplace safety evaluations. It allows organizations to efficiently conduct inspections, track compliance and manage safety protocols. With features such as customizable checklists, automated reporting and a user-friendly interface, this software ensures a systematic approach to identifying and mitigating potential hazards.

How does it benefit the manufacturing industry?

Intelex Safety Inspection software enhances safety standards in the manufacturing industry by automating and optimizing inspection processes. Customizable checklists, real-time monitoring via mobile apps, and streamlined reporting enhance efficiency. It ensures compliance, prevents accidents and promotes a proactive safety culture, contributing to long-term sustainability through data-driven insights and continuous improvement.Why should you choose Intelex Safety Inspection Software?

Here are several reasons to choose Intelex Safety Inspection software:- Operational Efficiency: Enhances efficiency by automating and optimizing safety inspection processes, reducing manual workload and paperwork.

- Proactive Risk Management: Enables real-time monitoring through a mobile app, facilitating prompt identification and mitigation of potential hazards, preventing accidents.

- Compliance Adherence: Customizable checklists ensure that safety measures align with industry standards and regulations, promoting compliance and reducing the risk of regulatory issues.

- Data-Driven Insights: Centralized data storage and advanced analytics provide manufacturers with insights into trends, enabling informed decision-making and continuous improvement in safety practices.

What is Audit Management Software?

Audit Management software helps to streamline and automate the entire audit process within an organization. It facilitates planning, scheduling and execution of audits, ensuring compliance with regulations, systematic documentation and efficient tracking of audit findings for enhanced transparency and accountability.

How does it benefit the manufacturing industry?

Audit Management software is an indispensable tool for the manufacturing industry, ensuring compliance with regulations through automated processes. It streamlines audit planning, promotes transparent documentation of findings and facilitates continuous improvement. By providing data-driven insights, the software empowers manufacturing professionals to make informed decisions, optimize processes and elevate overall operational performance.Why should you choose Intelex Audit Management Software?

Audit management software brings substantial benefits to the manufacturing sector:- Compliance Assurance: Ensures adherence to manufacturing regulations and standards by automating audit processes, minimizing the risk of non-compliance and providing a systematic approach to meet regulatory requirements.

- Efficient Audit Planning: Streamlines the planning and scheduling of audits, optimizing resource allocation and reducing downtime, resulting in a more organized and effective audit strategy.

- Transparent Documentation: Facilitates comprehensive documentation of audit processes, findings and corrective actions, promoting transparency and accountability.

- Continuous Improvement: Identify areas for improvement through systematic tracking of audit results, contributing to ongoing quality enhancement and operational excellence.

- Data-Driven Decision-Making: Provides real-time insights and analytics derived from audit data, empowering manufacturing professionals to make informed decisions, enhance processes and elevate overall performance.

What is Customer Complaint Management Software?

Customer Complaint Management software is used to manage and streamline the handling of customer feedback, grievances and issues. It provides a centralized platform for manufacturing organizations to efficiently capture, track and resolve customer complaints, ensuring timely responses, enhanced customer satisfaction and valuable insights for continuous improvement in products and services.

How does it benefit the manufacturing industry?

Intelex Customer Complaint Management software ensures prompt identification and resolution of product or service issues, leading to continuous quality improvement and heightened customer satisfaction. The software's systematic tracking enhances compliance with industry standards, while efficient communication creates trust and loyalty. By streamlining complaint resolution processes, it improves operational efficiency and provides crucial insights, allowing manufacturers to meet market demands effectively.Why should you choose Intelex Customer Complaint Management software?

Choosing Intelex Customer Complaint Management software provides distinct advantages including:- Quality Improvement: Promptly identifies and addresses issues, leading to continuous quality enhancement and heightened customer satisfaction.

- Compliance Tracking: Systematically tracks and resolves complaints, ensuring adherence to industry regulations and standards.

- Cost Reduction: Reduces the cost of poor quality by addressing issues early, minimizing the impact on production efficiency and resource utilization.

- Enhanced Communication: Fosters trust and loyalty through efficient communication with customers, while providing valuable insights for process improvement.

What is Permit Management Software?

Permit Management software enhances and automates the process of issuing, tracking and managing permits within an organization. It ensures an effective approach to granting permissions for activities such as maintenance or hazardous work, enhancing safety, compliance and operational efficiency by providing a centralized platform for permit creation, approval and monitoring. The software helps organizations maintain a clear record of permitted activities, mitigating risks and facilitating regulatory adherence.

How does it benefit the manufacturing industry?

Intelex Permit Management software ensures an efficient approach to issuing and managing permits for hazardous tasks. It enhances safety by enforcing compliance with regulations, streamlines procedures through centralized permit workflows and mitigates risks associated with specific activities. The software facilitates documentation, automates processes and establishes accountability, contributing to a safer and more efficient manufacturing environment with improved regulatory adherence and streamlined workflows.Why should you choose Intelex Permit Management software?

Here are several reasons for choosing Intelex Permit Management software:- Workflow Automation: Automates permit workflows, reducing manual errors, improving consistency and expediting the permit approval process, leading to quicker turnaround times for project initiation.

- Risk Mitigation: Enables organizations to assess and mitigate risks associated with specific activities by requiring thorough evaluations before issuing permits, minimizing the potential for accidents or disruptions.

- Documentation and Reporting: Provides a centralized repository for permit documentation, making it easier to track and report on permitted activities.

- Accountability: Establishes clear accountability by tracking and recording all permit-related activities, creating an audit trail that helps in case of incidents or regulatory inquiries.

1 877 932 3747

1 877 932 3747